How to Protect Drivers & Increase Efficiency with No-Touch Transactions

By Frank Adelman – CEO of Transflo

The electronic logging device (ELD) mandate was a catalyst for digital innovation in the transportation industry and the COVID-19 pandemic the accelerant.

When published on Dec. 16, 2015, the ELD rule gave carriers exactly four years to comply with a final deadline. New innovations flooded the market during as carriers re-evaluated their mobile strategies during this period.

The ELD deadline was in the rearview mirror when the COVID-19 pandemic hit in March 2020. The crisis gave motor carriers, logistics providers and shippers a mandate to safeguard the health of essential workers.

Social distancing became imperative, yet drivers were still picking up paper bills of lading (BOLs) from shippers and getting signatures from receivers. As it stood, drivers could not rid themselves of paperwork until after making a delivery and using truck stop scanning or mobile applications to capture signed proof-of-delivery (POD) documents.

Recently, a new round of digital innovation has emerged with cloud-based platforms that can seamlessly transfer documents and automate load tracking, among other routine communications. The most essential components of these contactless freight platforms are explained below.

Part 1: The electronic BOL

Rather than print shipping documents, shippers and receivers can send BOLs electronically to cloud-based platforms connected with carriers, logistics providers and drivers. For added efficiency, the platforms can integrate the flow of data and documents with the transportation management systems (TMS) of each party.

As soon as electronic BOLs enter the cloud platform, drivers can receive the eBOLs associated with loads assigned to them. As part of the process, the driver is notified by a mobile app that the document is received and ready for use before arriving to a load pickup.

If a shipper does not send an eBOL in advance, drivers can use the mobile app to capture and transmit an image of the paper BOL as soon as they get it from the shipper. The document can be automatically indexed by the cloud platform and associated with the shipper, receiver, carrier and driver accounts for all parties to have access.

Part 2: Electronic POD

When a driver arrives to make a delivery, rather than get a signature in person, the eBOL associated with the load can be emailed or texted to a receiver to sign electronically using any device.

For added convenience, this electronic POD process can be automated. A cloud platform can mark the location of the receiver by using the address on the eBOL or the order in the TMS of the carrier or logistics provider. The document can be automatically sent to the email or phone number of the receiver on file for a signature when the driver arrives.

This geofencing feature also can trigger location-specific forms and workflow. A shipper or receiver may want drivers to use a specific form or process for arrival check in, for example.

Drivers need instant visibility of the ePOD status, or they might otherwise leave the location without getting a signature. As soon as the ePOD is signed, the mobile app can give the driver confirmation the process is complete for a green light to depart.

Step 3: Managing exceptions

Nothing in transportation goes exactly according to plan. Shippers, receivers and drivers will still need to annotate an eBOL with detention events and damaged freight, among other types of exceptions.

As part of the eBOL and ePOD process, a driver could annotate the document with a picture of damaged freight. The cloud platform could also record the time of arrival and departure and annotate the eBOL before the receiver signs off to record a detention event.

Once the ePOD process is complete, the cloud platform may have additional exception management capabilities. Optical character recognition (OCR), for example, can be used to validate document types, extract data, identify and correct exceptions before the documents and data flow into back office systems.

Step 4: Expanding the footprint

An important consideration for deploying contactless freight transactions is the industry footprint of technology vendors.

Suppose a transportation company wants to deploy an eBOL and ePOD process for both its asset and non-asset logistics divisions. The company could roll out both quickly if the mobile app that its own drivers use for document capture is the same one that its partner carriers already use for its logistics division.

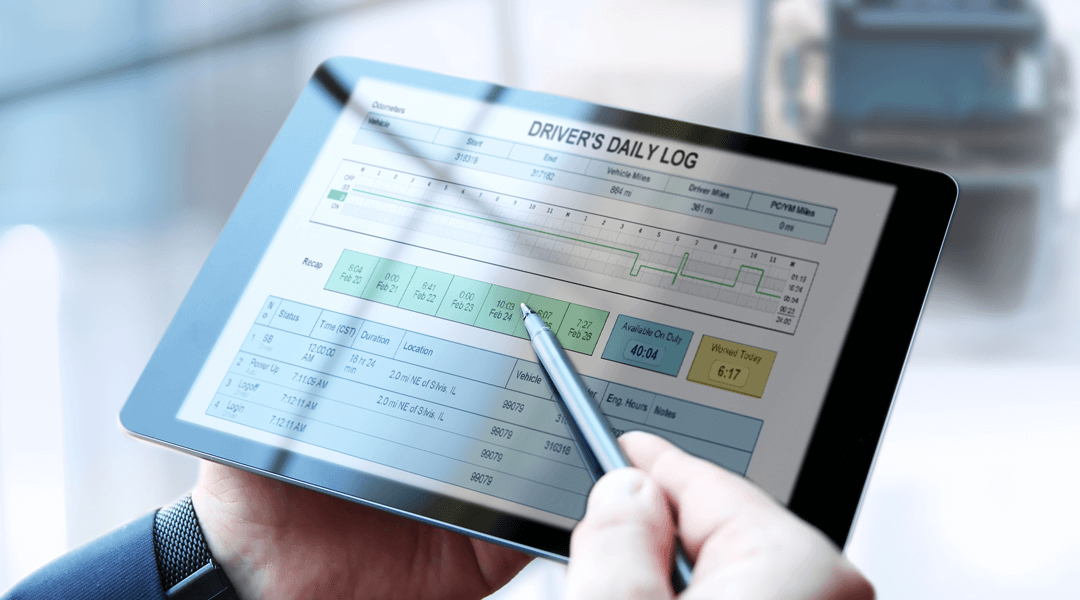

For a larger footprint, some technology providers also have full-featured mobile driver apps. Besides having document capture, mobile apps can include navigation, weigh station bypass, load permits, fuel prices and also be connected to a fleet management platform with telematics and ELD functions.

The expansion of mobile technologies and cloud platforms that have shared connections with supply chain partners are delivering benefits that surpass protecting drivers and frontline workers. The eBOL and ePOD processes are now part of expanded platforms that connect all parties and automate freight transactions to achieve new levels of efficiency.