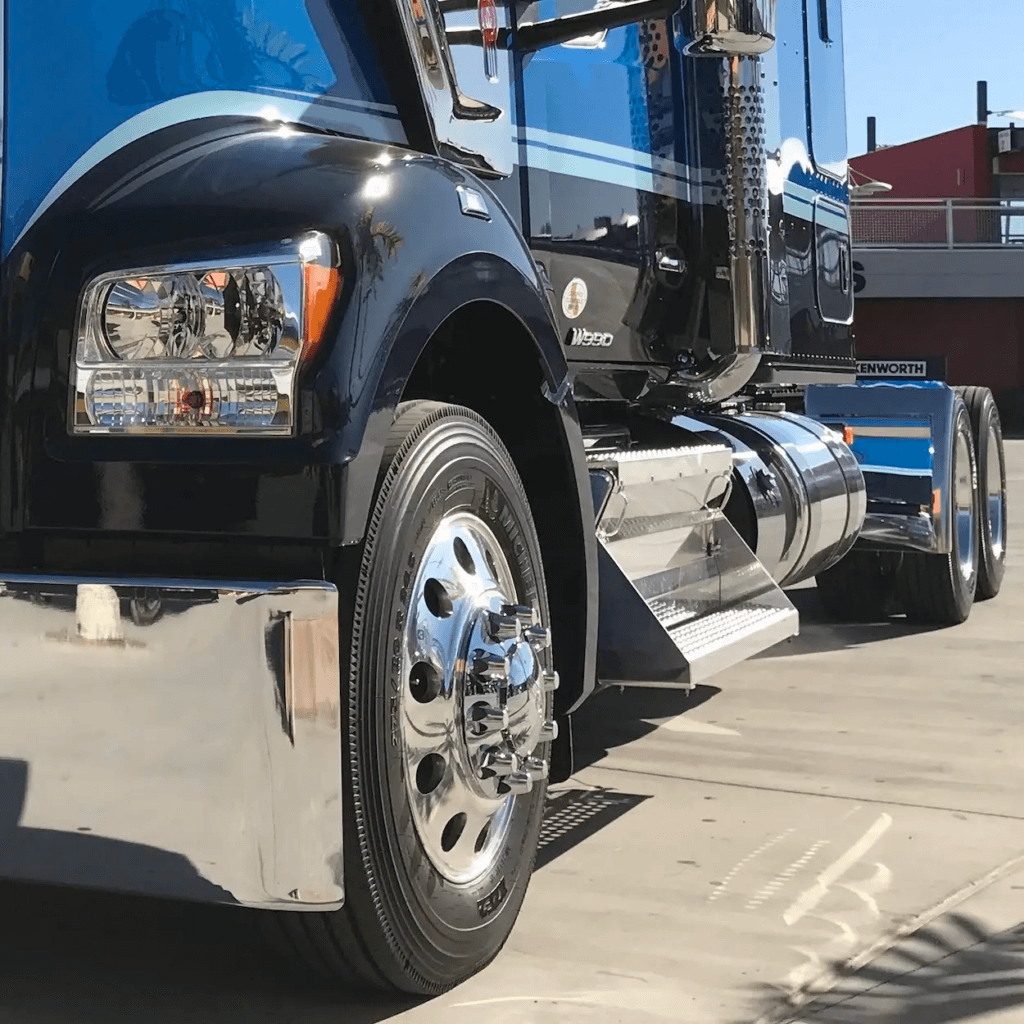

Five Ways to Extend the Life of Your Truck’s Tires

Summer Trucking Maintenance

For something with no moving parts, a commercial truck tire is a complex piece of equipment, constantly flexing and subject to fluctuating temperature, load weights, and inflation pressures.

Neglect can lead to unplanned downtime, higher running costs, increased safety risk, wrecked casings, and hard hits to your Compliance Safety Accountability (CSA) score. This is especially true in the summer, when temperatures heat up.

How can you get more service life out of your commercial tires?

Here are five simple steps you can take:

1. KNOW THE RIGHT PSI FOR THE TIRE

Running a truck or trailer tire at 20 percent under recommended inflation pressure generates excess heat and flexing that can reduce tire mileage by 15 percent and can damage the casing. It pays to keep your tires at their proper PSI.

Recommended inflation pressures vary according to tire size, load type/weight, and other factors, so refer to your tire supplier’s published load chart for the correct air pressure for each individual tire.

Note: Pressure recommendations are set for cold tires. So, don’t take air out of a hot tire that’s over-inflated by a few PSI.

2. STICK TO THOSE INSPECTIONS

Whether it’s by the mile or by the hour, establish inflation inspection intervals for every vehicle. Outfit each cab with a calibrated pressure gauge, invest in flow-through valve caps so operators can check pressure and add air without removing the valve cap, and use your Transflo Mobile+ app to communicate proper pressures to drivers and technicians.

Of course, ambient temperatures affect tire pressures: the rule of thumb is that for every 10-degree F decrease in temperature, inflation pressure will drop 2 psi. It’s best to check vehicle tire pressures first thing in the morning after the tires have cooled down overnight.

Note: Plan to inflate tires more often during colder months of the year.

3. USE YOUR HANDS

Your best tire-inspection tool is with you all the time: your hands.

You can diagnose a lot of problems by running a hand over the tread and sidewall to feel for cuts, cracks, and other abnormalities. If you see or feel protrusions—especially blisters or bulges—call for service right away.

4. PROMOTE CONSISTENT TREAD WEAR

For optimum tread wear, tires should be as alike as possible across the same positions. On dual assemblies, the outside diameters and tread depths should have no more than 2/32-inch tread depth difference between duals.

It’s also wise to have the same tread design on both positions of an axle.

5. READ UP & GET HELP

Section 393.75 of the FMCSA regulations pertains to tires, and it’s a good guide to the types of damage, defects, load restrictions, and inflation issues that can put a vehicle out of service.

Also tap into the resources of your tire supplier. Tire manufacturers publish maintenance tips and inflation pressure guidelines, and most local dealers offer training sessions for drivers and shop personnel. They can also help you establish a record-keeping system so you can manage cost and wear. All you have to do is ask.